Blogs

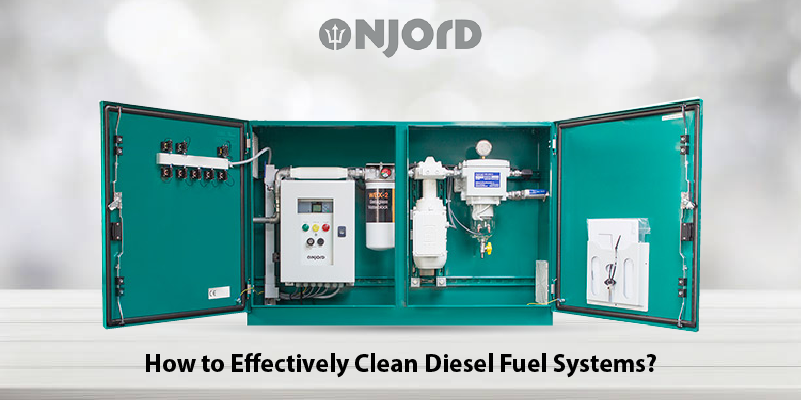

How to Effectively Clean Diesel Fuel Systems?

One of the common problems with deploying a diesel generator is fuel storage—which presents many challenges over a long time. While you might not be sure to stock up or leave a full tank sitting for an extended period, the contamination issue becomes much greater the longer it is kept. In turn, it may damage your generator and cause a breakdown when you need power for operations.

However, if you plan on storing diesel for a certain time, you can prevent contamination through a process called fuel polishing. Essentially, it removes impurities and reduces the chances of damage occurring. Here's how fuel polishing cleans your diesel fuel tank and why it is needed.

Filtering Diesel Fuel System

One common way of keeping water contamination and debris from forming in stored fuel for diesel engines is through filtration. During this task, diesel passes through progressively narrower filters, trapping suspended solids and letting fluids pass through. This helps in removing debris, sludge, and sediment from the fuel. Some diesel fuel filtration systems also offer the ability to clean water from diesel through absorption.

However, relying on filtration alone may overwhelm the filters. Frequent filter changes are a sign of overworked filters and poor fuel quality.

You must know that diesel fuel filter cleaning is a necessary step but not sufficient by itself. Sticking to a maintenance plan is a better option to avoid frequent fuel filter changes down the line!

What Does Fuel Polishing Treat?

Filtration is just one stage of fuel polishing, a technical cleaning process that removes sediment, water, and microbial contamination from diesel fuel engines.

During this process, the fuel is filtered from the tank through a special process that involves filtration, centrifuges, and coalescers. Advanced filters help capture suspended particles and water separated from diesel by a centrifugal force. Water-blocking filtration media then absorbs if there's any residual water.

Fuel polishing is more thorough than filtration alone in eliminating contaminants and keeping the diesel at industry requirements. For those with generators and backup power sources, this significantly reduces the chance of a breakdown or damage to the machine due to bad fuel.

Not All Fuel Polishing is Equal

While fuel polishing is a better alternative to filtration, it is crucial to note that not all companies that offer polishing services do a complete job. Some do partial filtration when pumping the diesel from the fuel tank, and few do enough to address the existing sludge at the bottom. Others stick a tube in the tank and suck out sludge.

When clean fuel is added to the dirty tank, microbial growth, and water issues return. This causes re-contamination practically before the technician has even left the site. In short, a partial fuel polishing process leads to wasted money and time.

How Often Should Fuel Polishing Take Place?

There are different schools of thought on the fuel polishing process and its frequency. However, most industry experts agree that it is best to do it at least once a year.

Usually, you need to remember that if you have an existing diesel fuel filtration system and utilize underground tanks that are free from water contamination, the need for fuel polishing is limited to just annually. Those with tanks more susceptible to contamination or storing higher amounts of diesel must consult an expert on an appropriate fuel polishing or fuel tank maintenance plan.

The bottom line

Njord Filtration is an excellent choice if you're looking for a reliable company to help with the fuel polishing process. We offer affordable fuel maintenance contracts and fuel filtration products that ensure your diesel is ready for use with your generator.

Our team is here to assist with all of your fuel storage needs. Contact us today for further details on high-efficiency diesel fuel filters.

Frequently Asked Questions

- Why is industrial fuel system cleaning essential?

Fuel system cleaning helps maximize machinery efficiency. Unclean fuel clog filters can damage injectors and impact the engine performance. - How often should fuel tanks be cleaned?

Fuel tanks should be cleaned as needed and inspected twice yearly. The frequency of inspections depends on usage and the environment. Regular inspections help avoid silt, water pollution, and microbiological growth in the fuel tank. - What are the common causes of fuel contamination?

Dirt and debris during refueling, water from leaks or humidity, diesel bugs in stored fuel, fuel degradation from storage are common reasons for fuel contamination.

Essential Diesel Filtration Tips for Cleaner and Healthier Marine Engines

Marine transportation like boats, ships, and yachts require a muscular build that allows them to keep you safe while navigating through unexpected environmental conditions. While there are multiple components that keep your marine vessel healthy, many people often deal with engine damage. One of the primary reasons why your boat’s engine is not performing well is due to contaminated diesel.

Due to long-term diesel storage in ships and boats, the fuel eventually stores dirt, water, and other harmful pollutants, making it challenging for the vessels to operate adequately. But how can you cleanse the diesel that is already on the ship? Njord Filtration’s marine diesel fuel filter system is here for the rescue.

In today’s blog, we will discuss how this diesel fuel filter can help you enhance the boat’s overall health. Keep reading to know more.

How to use them?

It is a simple process. The following is an expert guide on how you need to use these filtration systems:

- Install the system

First, ensure the filter is installed correctly on your vessel. There are three different filters: primary, secondary, and water-separating. (If this is your first time installing a filter, go through the user manual for better understanding. Also, install under expert supervision.) - Filter Process

Once you have installed the system, it will work in the following ways:

- Separate water: The water filtration will collect the stored water from the fuel and cleanse it.

- Filtering out particles: After the water filtration process is successful, the primary filter will collect the dust particles, enhancing the fuel flow.

- Polishing: Once done, the secondary filter will separate the minute dirt and debris from the fuel. After this diesel fuel filtration and purification process, your diesel is polished and fresh.

- Separate water: The water filtration will collect the stored water from the fuel and cleanse it.

Precautions you must take

As easy as it may seem, fuel filtration can be challenging. Besides, one wrong move and your health and your marine’s engine may be compromised. That is why our experts have listed the focus precautions you must take when using a diesel fuel filter:

- Correct system

In many cases, the filtration systems do not fit perfectly due to incompatible designs. Ensure that you select one that supports marine vessels. - Study the manual

We understand that user manuals can be long and boring, but you need to learn and understand every bit of the system to reduce the chances of potential risks. So, review the manual before using the filter system for everyone’s safety. - Regularly maintain it

The diesel engine fuel filter maintenance must be your priority post-installation. Regularly look for leaks and test the quality of the fuel for improved performance. Apart from that, also ensure the fuel tanks are clean and unclogged. - Do not let the filter overload

Always remember to check for overloaded filters. Not doing so can put a negative strain on the filtration system. - Spare parts

Always keep spare parts and tools for emergencies.

What Makes Njord Filtration System the Best Choice?

It is not just us; our testimonies also scream authenticity and high value when choosing the Njord filtration system. The primary reasons why we are widely known in the industry are mentioned below:

- Advanced technology

Our modern and advanced filters promise top-notch technology when removing dust particles from the fuel. - Sustainable

Our diesel fuel filter for engine protection ensures eco-friendliness, keeping your marine vessel and environment clean. - Meets standards

We proudly say our diesel filtration systems meet the emission standard, making them more valuable.

(Also read from our previous blogs: The Importance of Fuel Polishing Systems for Diesel Generators)

Bottom Line

Managing and taking care of marine diesel can be a challenging task as not keeping it clean and polished can cause engine trouble, even during the voyages; and as we know, finding a mechanic in the middle of the sea does sound like mission impossible. So, to save yourself from a problematic situation like this, you must choose the Njord Filtration’s diesel fuel filter system because we offer expert technical care that ensures a swift trip and a healthy engine.

For more information or details, you can contact us here.

Top 8 Signs Your Fuel Needs Polishing

Hundreds of millions of gallons of diesel fuel stored around the world have yet to be used. The equipment used at military sites, hospitals, truck fleets, and ships must be able to handle a lot. The fuel stored on-site is a valuable asset that needs to be properly managed and cared for.

Proper fuel care can cause problems such as clogged filters, engine damage, and poor performance. A fuel polisher can help prevent these problems by actively removing contaminants like water, sediment, and microbial growth from stored fuel, protecting its quality and making engine parts last longer.

Why Diesel Fuel Should Be Polished?

Diesel fuel polishing removes impurities like water, sediment, and microbial growth that can clog filters, damage engine parts, affect the performance, and even cause engine failure. Keeping the fuel clean will improve the reliability and lifespan of your equipment, which is especially important for generators and other important systems where downtime can be expensive. The main reasons to use a fuel polishing system are:

- Protect fuel lines and injectors from impurities to prevent engine failure.

- Fuel polishing extends the filter, fuel pump, and other component life by eliminating contaminants.

- Polished fuel optimizes combustion and power production.

- Regular polishing reduces gasoline contamination-related emergency repairs and maintenance costs.

- Clogged filters generate unexpected downtime, while fuel polishing maintains reliable operation.

You May Also Like: The Importance of Fuel Polishing Systems for Diesel Generators

How Well Does Fuel Polishing Work?

To keep a facility or site that stores a lot of fuel running, especially for long periods, facility managers must follow fuel polishing methods. A fuel polisher for diesel tanks successfully removes different contaminants that might be present. These maintenance systems have polishing parts that remove dangerous pollutants in the fuel very well.

Most of the time, a fuel polisher for engines works automatically on a set time. The fuel will flow through many filtration steps in these systems, and each stage will do a different job of polishing it. Here's what the process generally has:

- Filtering process: A multistage filter system cleans the fuel by removing big things like dirt, rust, and water droplets.

- Technology for separation: Separators are used to take free water and emulsified water out of the fuel.

- Controlling microbes: Depending on the use, fuel polishing may include chemicals that stop microbes from growing.

Signs Your Fuel Needs Polishing

Many things can help you determine whether the fuel you've kept needs to be polished. Protecting energy sources is important, as top fuel quality works best for operational dependability.

Some of the signs that your fuel is dirty are a strong smell, a filter that keeps getting clogged, poor fuel efficiency, the engine not working properly, dark or cloudy fuel color, debris in the fuel, or fuel that hasn't been used in a long time. You should usually use a high-efficiency fuel polisher to clean your fuel. All of these are signs of dirt, water, or other impurities that can be cleaned off by cleaning the fuel.- Duration Of Storage

Polishing fuel sitting in a tank for a long time can be a good way to keep it clean, even if you don't see any problems right away. This is important, as contaminants can build up over time. - Quality Of Fuel

If you think the fuel isn't very good because of where you bought it or when loaded, fuel filtration and polishing can help it work better. - Maintenance Checks

Fuel polishing is recommended as a preventative step once a year, especially for essential machines that can't be shut down. - Chemicals Seeping Through an Unsealed Access Port

If the fuel access port isn't properly sealed, water, dirt, or other objects might enter the fuel source. This pollution can greatly affect the fuel quality and the engine's performance. - Water In The Filters And Separators On Board

If your internal filters and water separators catch a lot of water, this could be in the fuel tank. In such cases, fuel purification and polishing are needed. - Change The Engine Filter Often

If your engine filters need to be changed more often than normal, it's probably because contaminants are building up in the fuel. The thick sludge in your filters could be a sign of a much bigger buildup in the tank. - Sludge in the Fuel Tank

Filters with a lot of sludge are likely to be highly contaminated. If this sludge is not removed immediately, it can block filters, stop fuel flow, and damage engines. - Fuel That Is Cloudy Or Discolored

Check your fuel visually. Depending on the type and dye, clean fuel usually looks yellow, orange, or red. If the fuel is too cloudy, murky, or thick, it could mean it has been contaminated and needs to be polished.

Summing Up

Using a fuel polisher to improve the quality of your fuel will keep your engines going well and avoid costly repairs or downtime. By checking your system often and finding these problems early, you can keep it running at its best and make it last longer.

Want to use modern technology to clean your fuel system? Choose Njord Filtration for all of your fuel system polishing needs! Contact us for a quote for a fuel polishing system.

Frequently Asked Questions

- What are the common signs of fuel contamination?

Some of the common signs of fuel contamination are frequent engine filter replacements, excessive water in onboard filters or separators, sludge buildup in filters, cloudy or discolored fuel, and the presence of dirt, water, or other contaminants in the fuel supply. - How do I check if my fuel is clean?

Visually inspect the fuel. Clean fuel is typically yellow, orange, or red in hue (depending on type and dye). It may be contaminated if it appears cloudy, murk,y or has visible debris. - Can fuel polishing save me money in the long run?

Yes, by preventing costly repairs, downtime, and replacements caused by contaminated fuel, fuel polishing can save money and extend the lifespan of your equipment.

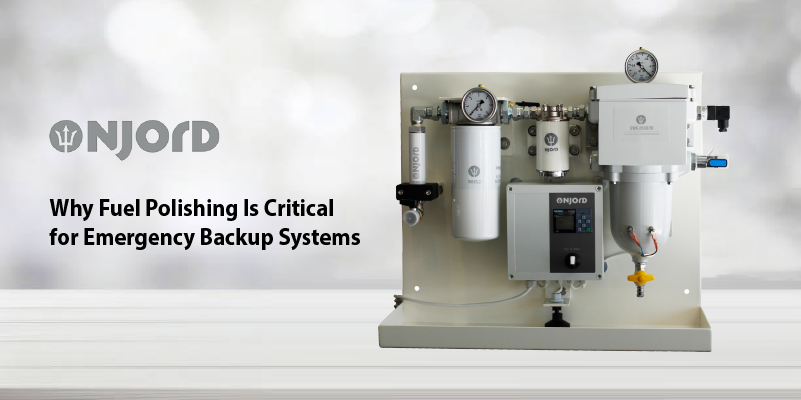

Why Fuel Polishing Is Critical for Emergency Backup Systems

This fast-paced world seeks reliability and rapid responses. We are not just talking about the internet here, but the emergency backups that let enlarged industries thrive without dealing with power issues.

Nevertheless, every industry, small to big, has adapted to emergency power backups, allowing them to allow power functionality immediately during the primary power line failure. This simple backup system comes with an Auxiliary Power Unit, Uninterrupted Power Supplies, and finally, the backup generator. These emergency backup systems support data centres, transportation centers, industrial plants, healthcare facilities, Military securities, etc.

While it plays a vital role in backing up power during an emergency, it is also essential to periodically polish the fuel for swifter functionality. So, in today’s blog, we will talk about why Fuel Polishing for emergency systems is vital and how Njord Filtration can help you for safe practices.

Keep reading to know more.

The Importance of Emergency Fuel Polishing System

The fuel often stores contamination like dirt, debris, water, and other microbial growth that can negatively affect the overall quality of the fuel, making it impure, toxic, and unsafe for the backup system. So when you get the Emergency diesel fuel cleaning, you:

- Improve the quality of the generator

As we mentioned, unpolished fuel can be unsafe for the backup system and generator. It can also cause clogged filters, which can lead to failed generators. - Keeps the fuel clean

Contaminated and unpolished fuel emergency systems can eventually degrade the overall system and slow it down. At the same time, clean and polished fuel will ensure smooth backup. - Regulatory

Due to extreme pollution, the government has set specific regulatory terms that every industry must follow to be eco-friendly. So, when you keep your fuel polished, you ensure that no toxic pollutants are released.

What Happens When You Avoid Fuel Polishing?

So, when you avoid diesel fuel polishing for standby systems, you can face the following challenges:

- System failure during emergencies

- Clogged filters and toxic pollutants

- Rusted tank, resulting in a damaged system

- Reduced lifespan of the system and its other vital components, leading to costly replacements

- Leakage leading to environmental violations

How to DIY Fuel Polishing for Emergency Systems

Thanks to modern technology, fuel polishing does not require professional help, especially when it is a small-scale power backup system. All you need to do is go through the user’s manual guide or check out the following tips for better clarity:

- Check fuel quality

First things first, start with checking the fuel quality. You can use a testing kit to check the content of debris, water, and mycobacteria. - Polishing equipments

Once you have checked the fuel quality, you must prepare for the next step, which is polishing the fuel. For this process, Njord’s portable fuel water removal for emergency systems will be the best choice.

(Also read from our previous blogs: Portable Fuel Polishing System: What is The Purpose of It) - Water Separator, circulator and filter

The water separator allows you to separate the water and dirt from the fuel. Once you have done this, the Njord filtration system filters the fuel to remove tiny contaminants, resulting in delicate, polished fuel. - Add stabilisers

Once the fuel polishing process ends, the stabilisers must be added to the fuel to keep it clean and contamination-free.

Precautions for Safe Practices

First of all, ensure to perform the fuel polishing under expert supervision if it is your first time. Apart from that, do keep the following things in mind for safe fuel polishing:

- Remember to wear protective gloves, glasses, and masks to avoid inhaling the gas.

- Ensure to polish the fuel in a well-ventilated area.

- Do not dispose of the waste in random spots. Ensure to follow the regulatory terms properly.

- Check the fuel quality regularly for instant polishing.

Bottom Line

Njord Filtration's fuel polishing for emergency systems allows industries to experience a smooth workflow. Our advanced technology is designed to fit the emergency systems perfectly.

For more information or expert consultation, you can contact us here.

Why Offshore Fuel Polishing is Essential for Safety in Emergency Situations

Offshore fuel polishing is crucial for maintaining emergency systems' safety, reliability, and efficiency in challenging offshore environments. Equipment on oil rigs, ships, and marine facilities relies on clean, high-quality fuel to function properly during emergencies.

However, contaminants such as water, sludge, and bacteria can reduce fuel quality, posing serious safety risks. That's where Njord Filtration comes in. We provide advanced offshore fuel polishing systems to remove these contaminants, helping businesses protect their equipment, comply with offshore safety protocols, and stay prepared for emergencies.

With our state-of-the-art offshore fuel filtration systems, Njord helps prevent fuel issues, extend equipment life, and maintain smooth operations offshore.

Find out more.

Preventing Fuel Contamination Offshore

Fuel contamination is a big problem in offshore environments, where fuel is often stored for long periods in tough conditions. Over time, water, sludge, dirt, and bacteria can get into fuel tanks, especially in humid or salty areas. These contaminants lower fuel quality, clog filters, damage engines, and make systems less efficient. In an emergency, this can cause equipment to fail, putting safety and operations in danger.

To solve this, an offshore fuel polishing system can ensure the removal of contaminants, maintaining clean and efficient fuel for operations. Fuel contamination prevention in offshore environments is crucial to avoid equipment failure and operational delays.

These systems:

- Remove Water

- Control Microbes

- Clear Sludge and Dirt

- Keep Fuel Stable

Keeping Emergency Systems Ready

In emergencies, such as power outages or equipment breakdowns, backup systems like generators and fire pumps need to work perfectly. For this to happen, they require clean, high-quality fuel. If the fuel becomes contaminated, it can lead to blockages, engine failure, or poor performance. That's where fuel polishing becomes essential. Offshore fuel filtration systems remove impurities, ensuring fuel quality and preventing damage to engine components.

By regularly cleaning the fuel, polishing systems prevent fuel lines and filters from clogging. As a result, engines continue to run smoothly when they are needed most. Fuel system protection offshore involves regular maintenance and filtration to avoid contamination and ensure engine reliability.

Ultimately, this process helps ensure that emergency equipment operates reliably, minimizes downtime, and reduces the risk of failure during critical situations.

Enhancing Safety and Compliance with Fuel Polishing

Clean fuel is key to preventing engine problems that could harm offshore operations and workers. Contaminated fuel can cause system failures, leading to safety risks. Regular fuel polishing helps keep fuel clean, reducing these risks and ensuring engines run smoothly.

Here's how fuel polishing improves safety and compliance:

- Reduces Engine Malfunctions: Prevents fuel-related failures that could disrupt operations.

- Aligns with Safety Protocols: Supports offshore safety standards by keeping systems reliable.

- Complies with Regulations: Helps meet safety and environmental rules by improving fuel quality.

- Minimizes Environmental Impact: Reduces emissions and the risk of spills caused by fuel system failures.

Prolonging Equipment Lifespan and Improving Fuel Efficiency

Contaminated fuel can damage important parts such as injectors, pumps, and filters in offshore systems. Regular fuel polishing helps keep the fuel clean, which protects these parts and extends the life of emergency equipment. As a result, there is less need for costly repairs and maintenance, allowing systems to stay in good condition for longer.

In addition, polished fuel burns more efficiently, ensuring that emergency systems work at their best when needed most. Since refueling opportunities are limited offshore, having clean and efficient fuel is very important. By keeping fuel quality high, fuel polishing helps improve efficiency, reducing the risk of system failure during critical times.

How Njord Filtration Helps with Fuel Polishing for Emergencies

Njord Filtration provides effective solutions to keep fuel clean and ensure that emergency systems work reliably when needed. Our polishing services help fix common diesel fuel issues like blocked filters, bacteria, sludge, and water contamination, which can cause engine problems in emergencies.

Njord's approach includes:

- Fuel Testing:

- Contamination Removal:

- Preventative Measures

- In-line Quality Monitoring:

By keeping fuel clean and meeting key quality standards, Njord ensures that emergency equipment works properly, reducing the risk of failures. Regular fuel polishing also prevents issues caused by unstable biodiesel fuels, ensuring systems are always ready when emergencies strike.

Want to ensure your emergency systems are always ready? Contact Njord Filtration today for reliable fuel polishing solutions.FAQs

- What is an offshore fuel polishing system and why is it important?

An offshore fuel polishing system removes impurities such as water, sludge, and particulate matter from fuel, ensuring it remains clean and efficient for use in offshore operations. - How does fuel contamination prevention work offshore?

Fuel contamination prevention offshore involves regular fuel monitoring, filtration, and cleaning to avoid water, dirt, and bacteria, which can damage engines and affect fuel quality. - Why is emergency fuel system safety crucial for offshore operations?

Emergency fuel system safety ensures that fuel storage and supply systems remain intact, preventing failures during critical offshore situations and ensuring reliable fuel access when needed. - What role do offshore fuel filtration systems play in fuel quality?

Offshore fuel filtration systems are essential for removing contaminants from stored fuel, maintaining fuel quality, and protecting engines and equipment from damage caused by impurities. - How can fuel polishing support emergency readiness offshore?

Fuel polishing for emergency readiness ensures that fuel remains clean and free from contaminants, enabling emergency equipment to function reliably in critical offshore situations.