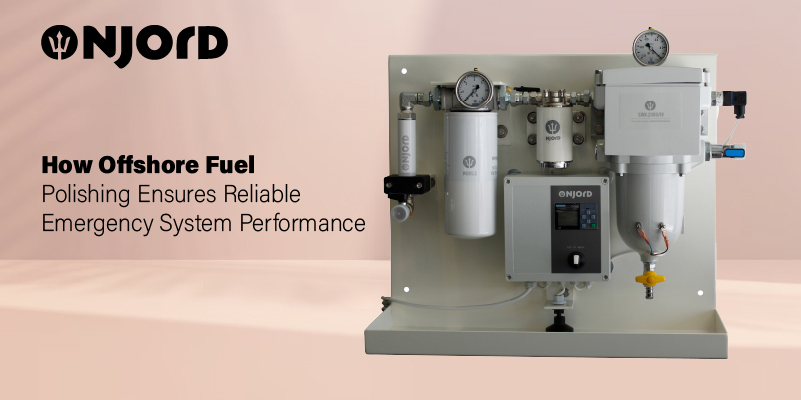

If you own heavy machinery that runs on fuel, you must know what an offshore fuel polishing system is. In simple terms, offshore fuel polishing involves restoring fuel by cleaning and removing dirt. It is typically used in marine vessels, such as ships. This process has gained immense popularity due to its quick and easy method of fuel cleaning without heavy manpower or budget. It helps you save time restoring the fuel for enhanced performance.

This blog will tell you everything you need to know about offshore fuel polishing and how it ensures that your fuel and machinery operate smoothly with Njord .

What are its benefits?

The following are the benefits of offshore fuel polishing:- Clean environment

It has been observed that burning fuel has been one of the most significant reasons behind global warming, resulting in acid rain and smog. This is why fuel restoration is essential, especially for large machines. It allows you to follow the regulations and promote greenery. - Runs the system smoothly

Offshore fuel polishing removes contaminations such as dirt, debris, water, etc., allowing you to experience enhanced and smooth functionality. This fuel contamination removal allows your generators to prevent breakdowns during emergencies. - Enhanced fuel

Old and contaminated oil typically degrades over time. When you polish the fuel, it tends to get cleaner and healthier, allowing you to experience a long-lasting fuel life expectancy. - Saves money

Contaminated fuel can damage the internal parts of your machines, making them unable to run smoothly. It can result in long-term damage to the parts, costing you much money and time behind the repairs. Note that fixing large generators or machinery can be very expensive. - Quick action

Leaving everything aside, you need to relearn the motive behind handling big machines—to take quick action while remaining safe. When you go for offshore fuel cleaning, you allow your machine to act quickly in an emergency.

How does offshore fuel polishing ensure safety?

First, let us understand what happens if you do not polish the fuel. So, over time, the fuel in the systems can be contaminated by:

- Dirt particles

Dirt particles and sediments can settle in the tank, eventually compromising the fuel quality and flow, essential for smooth performance. - Moisture build-up

Water build-up is one of the common problems, as it can lead to engine failures. In most cases, the environment leads to moisture inside the tank, slowing the process during emergencies. - Diesel bugs

The moisture build-up can also produce bacteria and fungi that can clog the fuel system and the engine. Treating the diesel bugs on time will allow you to prevent fuel system failure and run smoothly during catastrophic events. - Dissoluted fuel

Finally, stored fuel can get sticky and harmful over time, making it challenging for the engine to operate.

Fixing these issues can improve performance, clogged fuel passages, engine failure, and slow startup. You may ask how. Well, offshore fuel filtration:

- Filters out the dirt

The fuel filtration process filters out the dirt from the fuel, allowing the marine engines or generators to allow smooth fuel flow for better performance. - Separates water

Again, water is one of the worst components that can slow and damage your engine in no time. The offshore fuel polishing separates the water from the fuel. This process also ensures that even the moisture is worn out of the system to avoid rust or bacteria growth in the future. - Restore the quality of the fuel

Offshore fuel polishing restores the quality of the fuel, enhancing its purity and efficiency. This allows you to turn the old fuel into a fresh one that burns quickly without spreading toxins. - Fuel circulation

Almost regularly filtering the fuel will prevent contaminations from settling down in the engine.

(Also read from our previous blogs: Portable Fuel Polishing System: What is The Purpose of It )

Where to use offshore fuel polishing?

Offshore fuel polishing occurs when heavy machinery runs solely on fuel. Some of the significant areas where it is essential are mentioned in the following:

- Marine Vessels

Heavy engines, such as cargo, tankers, ferries, ships, etc., require fuel polishing technology to keep them healthy and long-lasting. Offshore fuel polishing is crucial and safe for marines planning long ocean trips. It ensures that marines experience a safe journey and return with functional engines and generators. - Backup Generators

Many big industries and offshore areas depend on backup generators during natural disasters. Regular fuel polishing allows these backup generators to back up electricity immediately without further delays. - Support Vessels

Multiple support vessels transport heavy goods via the sea route. A healthy fuel polishing system allows the engines to deliver the goods successfully and ensures a safe sail for the sailors.

Bottom Line

Even though it may sound like a regular thing, an offshore fuel polishing system for filtering out the contaminations from the fuel is an important task. This directly impacts our lives as well as the surroundings we live in. This is why, here at Njord, we offer safe fuel filtration that is easy to use and instantly lets your engine run on brand-new and healthy fuel.

To learn more about this product, you can contact us here.

FAQs

- How long does an offshore fuel polishing system last?

A Njord offshore fuel polishing system can last up to 10-15 years with proper servicing. - Do I need to hire experts to operate an offshore fuel polishing system?

We recommend only experts and professionals handle and operate the offshore fuel polishing system. They will make sure to utilize the system technically, separate the fuel from contaminations, and clean up after filtration.