One of the common problems with deploying a diesel generator is fuel storage—which presents many challenges over a long time. While you might not be sure to stock up or leave a full tank sitting for an extended period, the contamination issue becomes much greater the longer it is kept. In turn, it may damage your generator and cause a breakdown when you need power for operations.

However, if you plan on storing diesel for a certain time, you can prevent contamination through a process called fuel polishing. Essentially, it removes impurities and reduces the chances of damage occurring. Here's how fuel polishing cleans your diesel fuel tank and why it is needed.

Filtering Diesel Fuel System

One common way of keeping water contamination and debris from forming in stored fuel for diesel engines is through filtration. During this task, diesel passes through progressively narrower filters, trapping suspended solids and letting fluids pass through. This helps in removing debris, sludge, and sediment from the fuel. Some diesel fuel filtration systems also offer the ability to clean water from diesel through absorption.

However, relying on filtration alone may overwhelm the filters. Frequent filter changes are a sign of overworked filters and poor fuel quality.

You must know that diesel fuel filter cleaning is a necessary step but not sufficient by itself. Sticking to a maintenance plan is a better option to avoid frequent fuel filter changes down the line!

What Does Fuel Polishing Treat?

Filtration is just one stage of fuel polishing, a technical cleaning process that removes sediment, water, and microbial contamination from diesel fuel engines.

During this process, the fuel is filtered from the tank through a special process that involves filtration, centrifuges, and coalescers. Advanced filters help capture suspended particles and water separated from diesel by a centrifugal force. Water-blocking filtration media then absorbs if there's any residual water.

Fuel polishing is more thorough than filtration alone in eliminating contaminants and keeping the diesel at industry requirements. For those with generators and backup power sources, this significantly reduces the chance of a breakdown or damage to the machine due to bad fuel.

Not All Fuel Polishing is Equal

While fuel polishing is a better alternative to filtration, it is crucial to note that not all companies that offer polishing services do a complete job. Some do partial filtration when pumping the diesel from the fuel tank, and few do enough to address the existing sludge at the bottom. Others stick a tube in the tank and suck out sludge.

When clean fuel is added to the dirty tank, microbial growth, and water issues return. This causes re-contamination practically before the technician has even left the site. In short, a partial fuel polishing process leads to wasted money and time.

How Often Should Fuel Polishing Take Place?

There are different schools of thought on the fuel polishing process and its frequency. However, most industry experts agree that it is best to do it at least once a year.

Usually, you need to remember that if you have an existing diesel fuel filtration system and utilize underground tanks that are free from water contamination, the need for fuel polishing is limited to just annually. Those with tanks more susceptible to contamination or storing higher amounts of diesel must consult an expert on an appropriate fuel polishing or fuel tank maintenance plan.

The bottom line

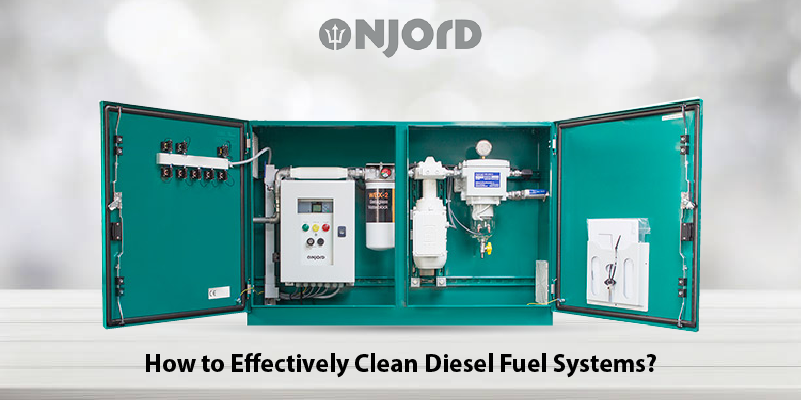

Njord Filtration is an excellent choice if you're looking for a reliable company to help with the fuel polishing process. We offer affordable fuel maintenance contracts and fuel filtration products that ensure your diesel is ready for use with your generator.

Our team is here to assist with all of your fuel storage needs. Contact us today for further details on high-efficiency diesel fuel filters.

Frequently Asked Questions

- Why is industrial fuel system cleaning essential?

Fuel system cleaning helps maximize machinery efficiency. Unclean fuel clog filters can damage injectors and impact the engine performance. - How often should fuel tanks be cleaned?

Fuel tanks should be cleaned as needed and inspected twice yearly. The frequency of inspections depends on usage and the environment. Regular inspections help avoid silt, water pollution, and microbiological growth in the fuel tank. - What are the common causes of fuel contamination?

Dirt and debris during refueling, water from leaks or humidity, diesel bugs in stored fuel, fuel degradation from storage are common reasons for fuel contamination.