Unplanned downtime caused by power outages can cost you thousands of dollars, if not more. Businesses, educational institutions, hospital facilities, and residential complexes heavily invest in power backup. It is an excellent step towards enjoying uninterrupted power supply even when the main source is off.

Maintaining the shelf life of a generator ensures a continuous power supply. There are many recommended best practices when it comes to fuel system maintenance. Regular fuel polishing is one such practice that you must be aware of.

Read on to learn more about fuel polishing, its benefits, and how it enhances the shelf life of diesel generators.

What is fuel polishing?

Fuel polishing is a process for cleaning hydrocarbon and oil fuels in storage tanks for future use. The stored fuel goes through a filtration process, extracting contaminants without fuel additives.

Contaminants include microbial growth, sediment, and bacteria whose presence reduces the generator’s efficiency. The fuel polishing process helps reduce the build-up of sludge at the bottom of a diesel fuel tank.

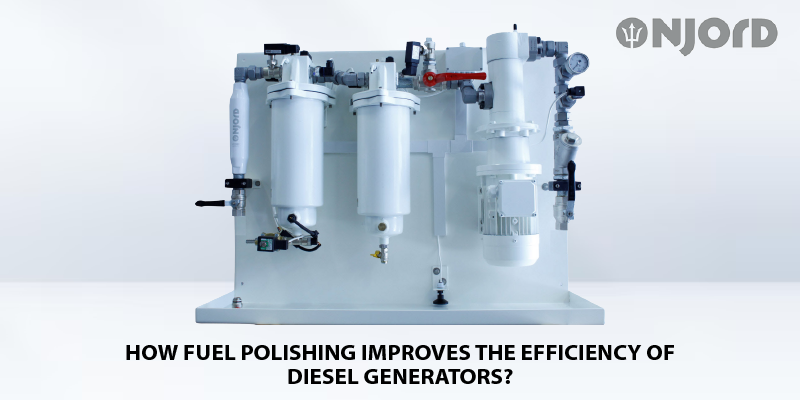

What is a fuel polisher system?

A fuel polishing system is a set of tools that uses filtration systems to clean the fuel. Some generators come with a fuel polishing system, and when this is the case, owners do not need an external fuel polishing service. If a generator does not have fuel polishers, an engineer can be hired by a generator maintenance service provider offering a fuel polishing service.

Today, industrial backup power systems have an attached fuel polishing system that can automatically run. Fuel polishing is an essential generator maintenance process that needs to be conducted at least annually.

Why is diesel fuel polishing needed?

Generators use different fuels. Those that use diesel fuel must store it for a long time, sometimes as long as ten years. However, the fuel may start collecting contaminants within six months of storage. As diesel fuel is used, it can pull in external dirt that settles at the bottom of the tank. Hence, the generators must have their fuel polishing systems.

Diesel fuel generators must follow regular fuel quality tests, followed by fuel polishing, which is a vital pillar of this process. The result is improved fuel quality and uninterrupted fuel supply.

Benefits of filtering fuel tanks

Here is how diesel fuel polishing can expand the shelf-life of generators:

- The fuel storage tank cleaning process prevents sludge and microbial contamination from building up in the fuel tank bottom and on tank walls.

- The fuel polishing system helps maintain fuel quality and clean out contaminants.

- It is equipped with water separators that remove water that has entered the tanks.

Impact on diesel fuel power backup

- Fuel purity increases fuel supply and enables the efficient running of generators. This process increases the time needed to provide backup power systems during a power failure.

- Reduced fuel contamination enables the generator to operate properly. It reduces breakdowns and extends the shelf-life of the generator. Moreover, it has a direct impact on cost savings.

- There is no need to facilitate regular fuel replacement, which is costly.

In conclusion

Generator maintenance is needed for reliable power backup. Fuel polishing is a vital part of this process. Without it, the fuel quality deteriorates over time, affecting the generator's efficiency and longevity. Hence, the generator should have a fuel polishing system.

The best approach is to partner with the experts at Njord Filtration, who understand the challenges and offer top-notch fuel filtration services. Contact us to schedule a service visit.